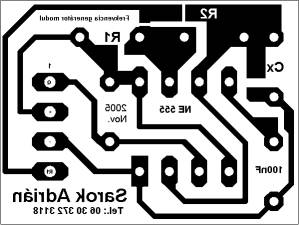

Here you can see that the toner has not been removed:

Making high-quality PCBs home (Home made method)

"The Ironwork Panel Production Method-In-Own Approach"

Principle:

The toner and laser printer toner (toner filler) are made up of very fine

dusty plastic particles (also).

It is known from the plastics that

it has thermosetting (eg bakelite) and thermoplastic (PVC, poly

carbonate, polyethylene …)

In addition, they generally resist most acids. These are important criteria for cutting the circuit board!

Photocopiers and laser printers would use thermoplastic dyestuffs based on their operation.

Their operation: The surface of a light-sensitive (often Si-containing) cylinder is electrostatically charged and then illuminates the subject (Optical

laser copier, laser printer with laser).

Where light has reached the cylinder, it loses its charge. Then the toner in the toner finishes "finely" and adds to the loaded parts.

In the next step, the electrostatic charge "pair" (electron deficiency) is transferred from the cylinder to the paper along with

the ink particles, then the paper passes through a heated cylinder that combines the ink particles into the paper (about 180°C).

In our case, the last step is the biggest problem, because we want to

transfer the print onto the copper surface of the blank pcb.

You can get "Ironing Technique" paper, but an arch is about 2-3$.

I experimented with something (Some examples that led to the solution):

1. I smeared an empty A4 sheet with a wallpaper sticker and smoothed it with an iron while it was drying.

After printing and "scrambling" the PCB design I simply extracted the glue on the paper.

(This solution has yielded better results than plain paper, but I did not get enough thick adhesive layer).

2. My second attempt was Aluminium foil. (Seriously!). If you could get thicker, it would be a perfect solution!

When printing, the bib is crumpled, so I made a drive to the top to get at least into the printer without wrinkling. This can be used very well

in ironing because it is visible on the back of the drawing. While ironing, smooth the film on the panel until the contour of the lines on the

back is fully visible. Then, you should simply rub the ALU foil with a small amount of Iron Chloride or household hydrochloric acid.

Caution Aluminum has a violent reaction with the solution and heat and produces chlorine gas !!!

The milling should only be carried out in a very well ventilated place !!!

If the foil has ceased to exist (stop gas generation), rinse the pan with water and drain the copper foil with the usual marinating liquid.

Do not contact the iron directly with the ALU foil as it may explode! Let us put a sheet of paper.

3. This is my last proven method:

Advantages: Less environmentally friendly, cheap, easy-to-use, high quality print.

The essence of this method is paper that needs to get sticky so that it can get out of the printer.

This is best for taking A4 paper in the paper shop. We can even throw the self-adhesive part

(Of course it can be used) and printed on the paper from which the self-adhesive part (good glossy surface) was removed.

Ironing:

If you print the draft plan on this glossy surface, there are only a few important rules to keep in mind:

-Do not pull the NYC drawings because they may be scratched or dirty.

-It always print the mirror image of the actual panel (including the text sections)

-It's not hot for the iron. The copier / printer ink melts at 180-200 ° C.

- Do not start ironing directly through the paper. First, place the fully defrosted, cleaned panel on the iron for about 20 to 30 seconds to

warm it up and then place the desired print with a piece of folded newsprint on the panel (with a newspaper to avoid dropping Hand),

then smear it with the iron a few times. Be careful not to slip the paper and then press it with newsprint again.

We repeat this until the entire design is properly adhered to. When done, you should leave some time to cool (about half a minute),

then gently pull the paper out. If done well, there is nothing on the surface of the paper.

The thing for this thing is that because the dye is melting around 180 ° C as a solder tin, it can be soldered even without removing the panel, but it needs to be heated a bit longer so that the Tin can be fed into the copper surface. Depending on the type of paint, two kinds of solvents can be used for washing: Acetone or lacquers (or benzine).

If you do not have one at home, then the well-known mechanical method (sanding, grinding) remains the same.

Good knot production for everyone. :)

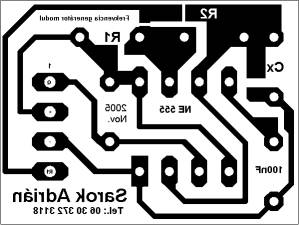

This is also done (see the basic circuit of the meteorological station):

Here you can see that the toner has not been removed:

A képen látható fenyőgyanta maradványokat könnyen eltávolíthatjuk denaturált szesszel!

Written by Adrián Sarok.

2006.