The

bulb problem often breaks down in Simson

Got a Simson S51b where

the bulb often burns out (Headlamp and rear position

indicator)

Unfortunately, the old coil burned down because a

larger bulb was installed in the headlamp (55Watt was installed).

The

factory Simson S51b headlight bulb is 35 / 35W. There is a metal

baffle around the filament of the passing beam.

For the driving

beam filament, this is not the case. The Simsons generally do not

have a voltage regulator for lighting.

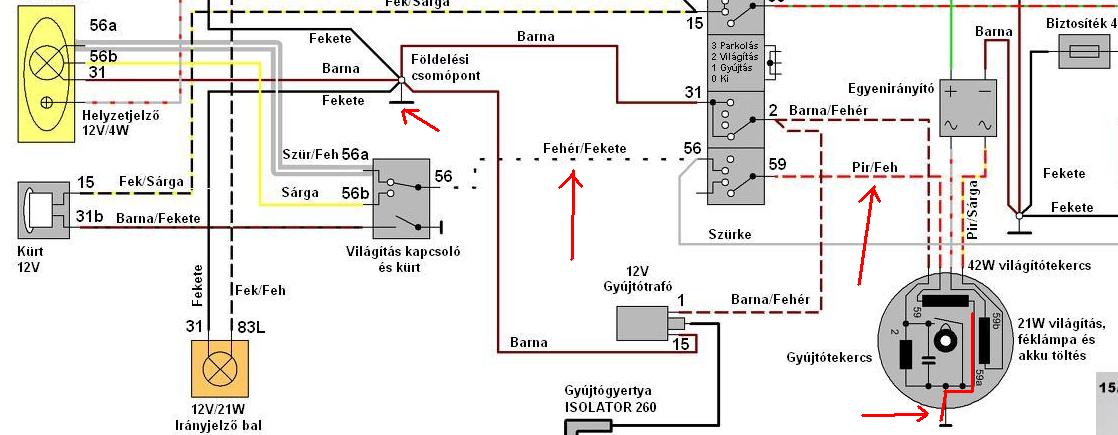

As the flywheel rotates,

the magnets on the flywheel induce voltage inside of the lighting

coil.

If we were not connect to anything, it would be up to

60-80V.

Under load, the voltage drops to about 10-15V as a

function of speed.

There's no rectifier or any other electronics,

just the light switch. It is important to have perfect contact

everywhere!

If, for example, The bulb socket on the front bulb

does not contact well, then the bulb on the rear will often go

out!

Always check the switch, as if the contact is faulty, it can

also cause surprises (mostly low brightness and charred switch).

Due

to the lack of electronics, alternating current goes to the bulbs, so

keep that in mind if you want to measure.

(It is worth switching

to 200V AC).

The

factory coil is made of 0.8mm wire, so it has higher resistance, the

new roll is made of 1mm wire and maybe the thread speed is not

exactly the same.

The coil is officially 42W. The front bulb is

35W, the back is 5W. The two together are 40W, 2W is a loss reserve

think ...

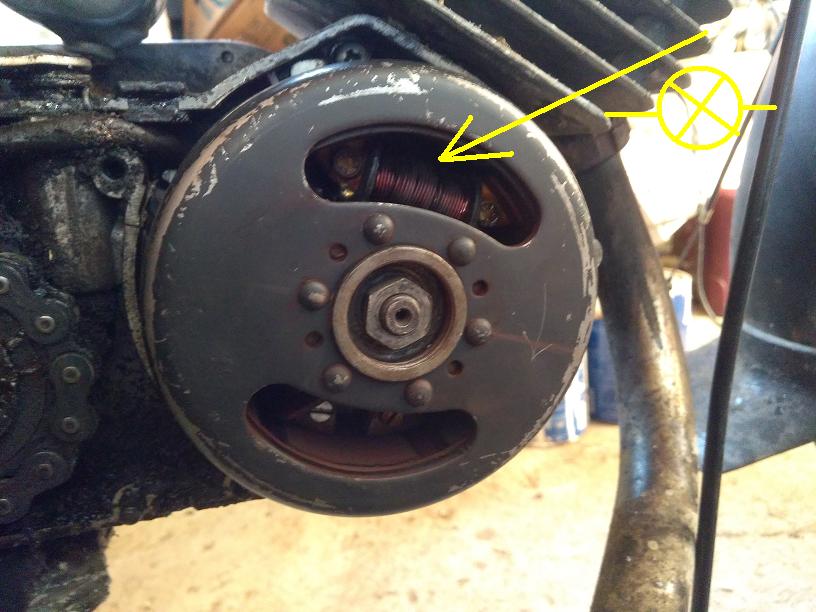

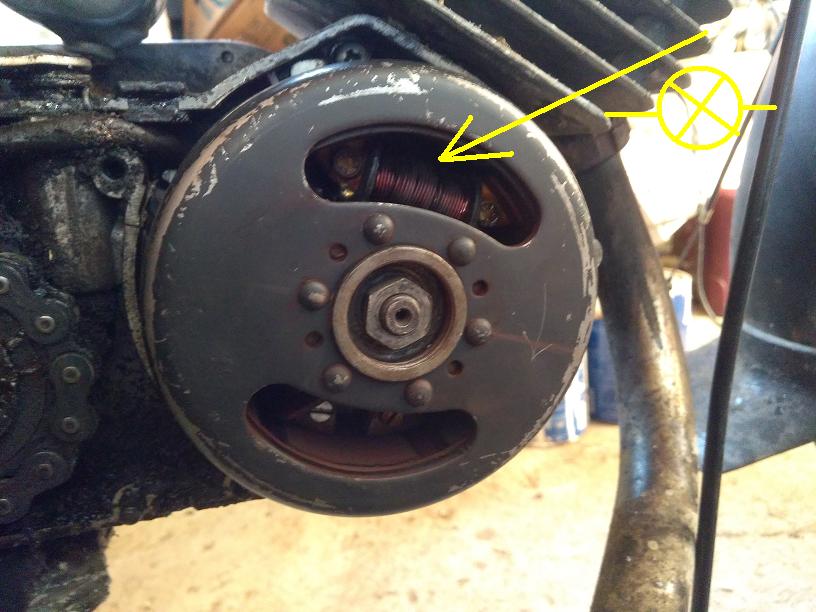

The

one above is the lighting coil (the picture still shows the old burnt

out).

After replacing the burned-out bulbs, I started the

engine (the headlamp does not work when stationary) and then removed

the tail light bulb,

I measured the voltage at the position light

(Here because there is less current and less voltage drop than the

front).

We also need to measure it from the front, because if

there is some contact error in the system, the voltage will be much

lower here.

A few tenths There was a difference between the two

bulbs because of the resistance of the wire.

Holding the

instrument to the terminals, I measured 10.5V, but as soon as I

pulled the throttle, the voltage went up to …

Of course,

the bulb always burned out.

Then came the thought of how to

reduce the tension …

The first thought is

to put up resistance. The problem is that a lot of heat would be

generated, so that would be a very poor solution.

With alternating

voltage on the coil, my second thought was to make a coil that could

be connected in series to limit the current.

I don't like to roll,

I should have iron core too, it gets warm and I should bind it and

then fix it somehow, somewhere …

Not good, I need another

idea.

Let's roll a few threads? This may work

because the tension will be lower if the speed is lower.

The

problem is that I wouldn't like to bundle the enamel wires factory

glued together, then solder them, remove the whole coil …

Should

we put a higher load? Parallel resistance or slightly higher

bulb?

This is not a good idea either, as the coil can burn and the

energy reduces the efficiency of the engine.

Finally,

since the system works so that the magnetic force lines start to

bypass the iron core under load (effect-response),

after a certain

load, the iron core is saturated anyway, the air gap was my next

idea.

The

air gap is defined by the height of the iron.

It provided a

simple solution. If I can increase the air gap, the induction and

voltage will decrease.

This allows the exact voltage to be

set. But the iron core is not adjustable and it would not be good to

drill such a hard material …

Finally, I decided to take off

the flywheel and start using the angle grinder to start increasing

the air gap by grinding the iron core down.

On first run, the

voltage went down to 16V. For the second up to 15.2Volt, the third

managed to set the shaft gas 14.4Volt, which is 10.2V at idle.

This

way, the bulb will certainly not burn out prematurely, since cars are

also designed for 14.4Volt

(12V batteries can be charged up to

14.4Volt, so generators are set up for this).

As you can see this is a

very sensitive operation. You should always grind a little, then

reassemble and measure.

I had to do this 3 times, but it is worth

the time because I don't have to change bulbs anymore.

Many people

install external circuits to protect the bulbs, but I think it's

always easier to have the right solution, as there are no extra parts

or connection points.

I hope I could help others with this

short story.

If you think you should support the site with the

price of a beer or cola, but this is of course optional.

Have a

good ride!

<<

Back <<

2019.11.13.