Adobe house renovation – parking place

Since

the plot is surrounded by 3 sides, 1 side with neighbor, so I can not

even get a bucket slip because there is no place to lay.

There is

a ditch from the street front, the other two roads are only 3-5m

"wide" (or rather narrow), so you have to restore the

carriage set that the previous owner has terminated. As a first step,

the fence has been broken down so that I can bring it.

6m3 gravel is "tired" from the fence with little help.

The crawler must be leveled because the bottom of the car is only 13 cm high, the border is 15 ...

Pickaxe to it

It's good to have saved the cement here :)

The old gate is not going to be used because the iron oxide of the time has been enough, so I decided to use a sliding gate, which would be a swing door.

I

did a sliding door at the weekend home, but the gravel truck rolled

the rail, which was wavy under its wheels. This and falling on the

rail avoiding the problem caused by the leaves. There is a site on

the side, just digging a bit from the hillside …

I had to

adjust the edge of the concrete here too.

The gate is also made. The room was already outdated, but the window was still worn (in principle)

Unfortunately,

there were no 6m profiles in the car, so I had to cut it in 2m pieces

so that I could get it back together.

Here I realized that the

concrete floor is not straight ... The welded profile turned 180

degrees, 3-4 cm away from the floor.

I had to cut and weld it

again. That's why the gate just got together in 4 hours. Alone, this

is not such a bad time, especially that

I'm not a welder (just

like masonry and plumber or gardener).

5.5 meter long room, 6 meter gate. :) Problem?

During the welding is sent a message to the apache's:

The rollers are also made (I did not cut the axle with an angle grinder and cut off the edges straight with lathes)

Material of roller supports: 40x10 flat iron. Maybe I'm still surviving. If I did not paint it, roughly 0.1mm would go rust every year, so it would lose in 100 years, but after about 70 years, it's possible to get wrecked. Then, at age 102, I could not care.

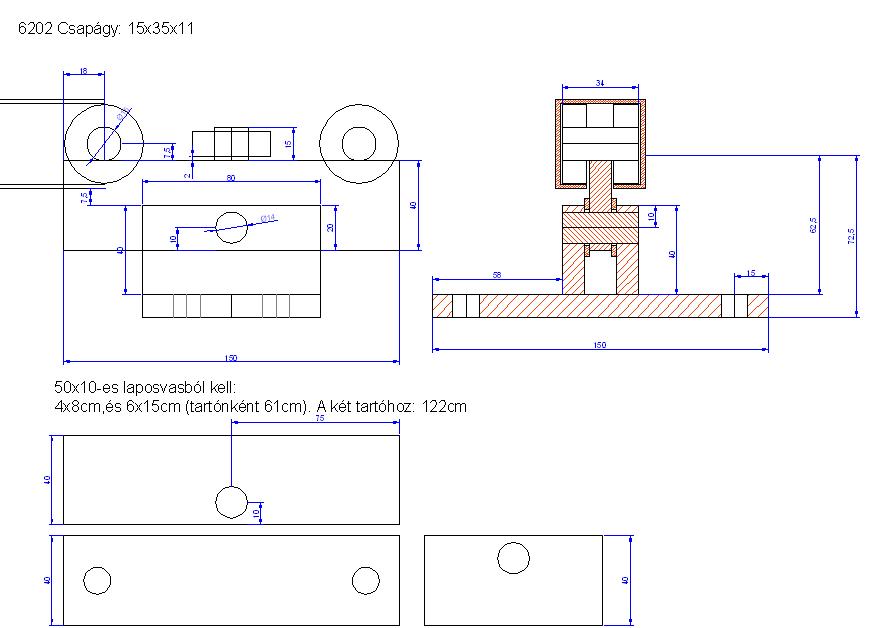

If there is someone who can imitate the float roller, I'll help, here is the drawing:

The

most remote part is the welding of the shafts:

The horizontal axes

are 34mm long, anywhere between the vertical 15-20mm (Diameter is the

same as the inner diameter of the bearing, which is 15mm)

The rail

is made of a 40x40x2mm hollow section that has to be cut lengthwise

to fit the 10mm flatbed easily (12mm gap).

Thighs blown in 3 layers:

Concrete:

Steel mesh laid

The gate position is laid down, feet and threaded threaded stems are prepared

Car park place:

Now it's ready:

During the concreting process I gathered the scattered concrete and made the stairs of the sidewalk into ramp

The place of the gate (The appearance cheats, does not drop inwards, but is horizontal. In fact, the fence and the road rise):