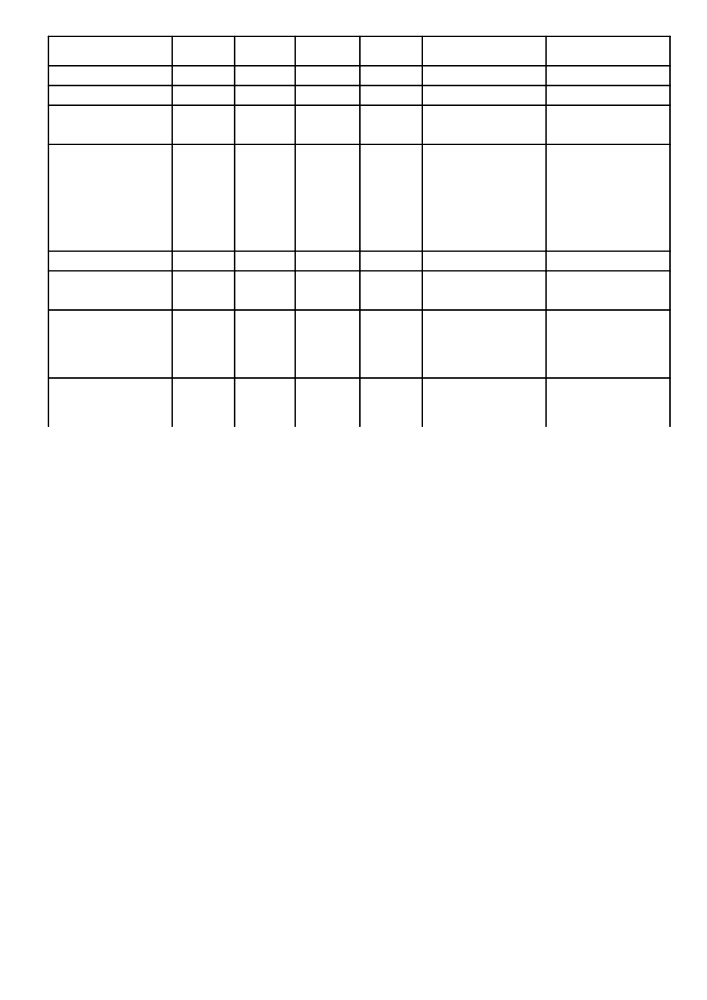

Defect indication on control panel

Possible malfunction

Method of malfunction

elimination

2, 4, 6, 7, 10

1 interface

8 interface

Defect description

interfaces

HM 3045,

HM 3068

2. HM 3060

9 interface

HM 3050,

HM 3069

7. HM 3072

Hm 3055

HM 3071

HM 3070

1

2

3

4

5

6

7

Foaming malfunction

—

—

—

—

1. Detergent inappropriate for

1. To replace detergent

WM is used

2. Big quantity of detergent is

2. To reduce dose of

used

detergent

Module (electronic block)

SEL

−••••

)

●○○○●

—

The selector is faulty

The control module or the

selector defect

electronic block is to be

replaced

the temperature sensor defect

«F 2»

−•

○○●○○

1. Break of wire in strip or

1. To check resistance between

20

°

or

unreliable contact

contacts of the temperature

or

sensor and electronic block,

20

°

○○○●○

reliability of their fastening. If

(for 10

th

interface

break of wire or unreliable

WMs only)

contact is detected, to eliminate

defect.

2. The temperature sensor is

2. To check resistance of the

faulty

temperature sensor from 5,7 to

6,1 kiloohm. In case of

malfunction, to replace heater.

3. The control module or the

3. The control module or the

electronic block is faulty

electronic block is to be

replaced

Heater malfunction

«F 3»

−••

○○●●○

○○○●●

1. Break of wire in cord or

1. To check resistance between

unreliable contact

contacts of heater and

electronic block, reliability of

their fixing. If break of wire or

unreliable contact is found out -

to eliminate defect

2. The heater is faulty

2. To check resistance

between contacts of heater

from 25 to 31 ohm. In case of

malfunction, to replace heater.

3. The control module or the

3. The control module or the

electronic block is faulty

electronic block is to be

replaced

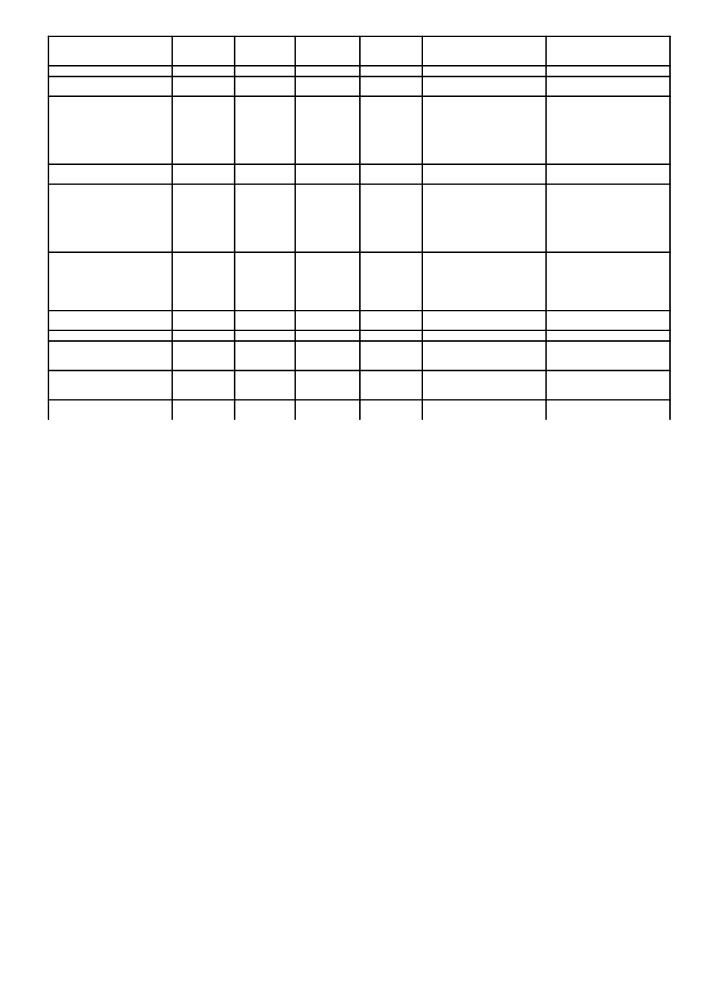

Drainage pump malfunction

«F 4»

−•

○●○○○

○○●○○

1. The drainage hose is

1. To install the drainage hose

installed wrongly.

according to IM.

2. The drainage hose is

2. To clean the drain hose.

clogged.

3. The vane of drainage

3. To clean electric pump body

electric pump is stalled. There

drainage from extrinsic items.

are extrinsic items in electric

To make sure that the vane

pump body.

rotate freely.

4. The drainage coupling is

4. To check correctness of the

installed wrongly.

drainage coupling installation

in regard to absence of bends,

sagging, mismatch of marks. If

incorrect installation is

detected, to make

corresponding correction. In

case it is not possible to

eliminate sagging, the

drainage coupling shall be

replaced.

5. The drainage coupling is

5. To clean the drainage

clogged

coupling

6. The ball in the drainage

6. To pour out water from WM

coupling is sticky

through tube, to replace the

drainage coupling (if

necessary)

7. Break of wire in cord or

7. To check resistance

unreliable contact

between contacts of electric

pump and electronic block,

reliability of their fixing. If

break of wire or unreliable

contact is found out - to

eliminate defect

8. Electric motor of drainage

8. To check resistance

electric pump is faulty

between contacts of electric

pump from 160 to 210 Ohm. In

case of malfunction, to replace

drainage electric pump.

9. The control module or the

9. The control module or the

electronic block is faulty

electronic block is to be

replaced

Water filling defect

«F 5»

−••

○●○●○

○○●○●

1. The tap is closed

1. To open the tap

2. Small water head (the

2. To check water head

pressure below 0,05 MPa)

3. The filling hose is clogged

3. To disconnect the filling

hose from WM. To check

passing of water through the

filling hose after opening of the

tap. If water does not pass, to

clean or replace the filling

hose

4. The filling hose filter or the

4. To clean the filling hose

electric valve filter is clogged

filter or the electric valve filter

5. Break of wire in cord or

5. To check resistance

unreliable contact

between contacts of electric

valve and electronic block,

reliability of their fixing. If

break of wire or unreliable

contact is found out - to

eliminate defect

6. The electric valve is faulty

6. To check resistance

between contacts of electric

valve from 3,5 to 4,5 kiloohm.

In case of malfunction, to

replace drainage electric

valve.

7. Control module or electronic

7. To replace control module

block is faulty

or electronic block

Motor stop malfunction

«F 6»

−••

○●●○○

○○●●○

Electronic block is faulty

To replace electronic block

Line frequency malfunction

«F 7»

−•••

○●●●○

○○●●●

1. Line frequency outside

1. To call energy serviceman

range

(50 ± 1) Hz

2. The control module or the

2. The control module or the

electronic block is faulty

electronic block is to be

replaced

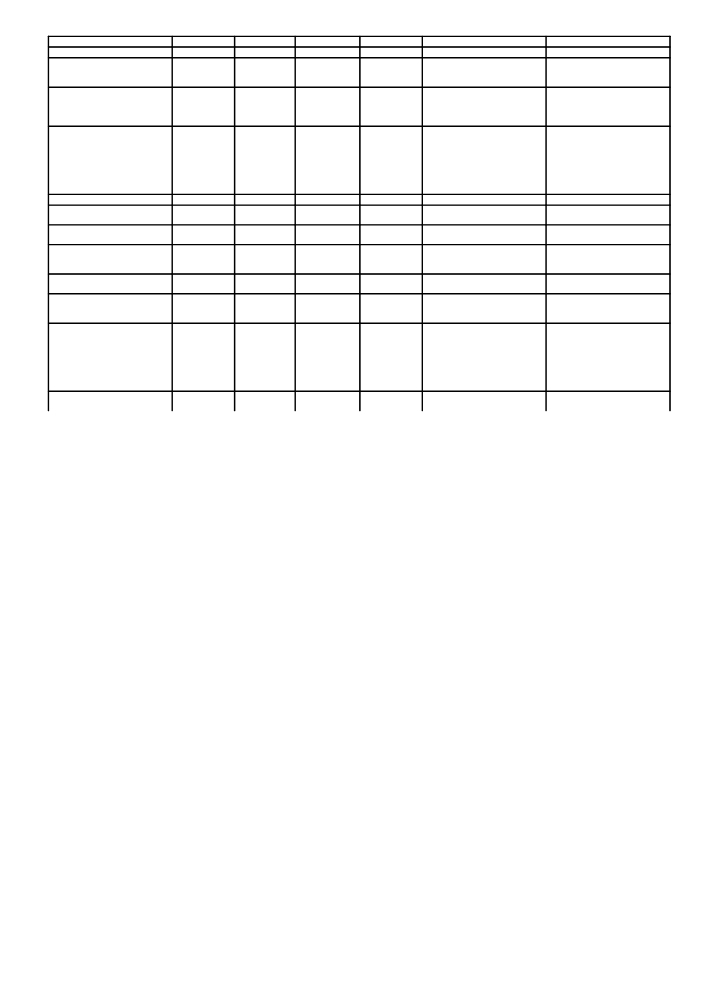

Overflow malfunction

«F 8»

−•

●○○○○

○●○○○

1. The tube of relay sensor is

1. To replace or install the

damaged or fallen down

tube of relay sensor

2. The relay sensor is faulty

2. To replace the relay sensor

3. The electric valve is faulty

3. To replace the electric valve

4. The control module or the

4. The control module or the

electronic block is faulty

electronic block is to be

replaced

Rotation sensor defect

«F 9»

−••

●○○●○

○●○○●

Motor overheating

1. Infringement of operating

condition (loading, voltage and

frequencies). To consult the

consumer.

Break of wire in cord, in

2. To check resistance

electric motor or unreliable

between contacts of electric

contact

motor and electronic block,

reliability of their fixing. If

break of wire or unreliable

contact is found out - to

eliminate defect

Electric motor is faulty

3. To replace electric motor

Control module or electronic

4. To replace control module

block is faulty

or electronic block

Triac of electric lock of door

«F 10»

−••

●○●○○

○●○●●

1. The electric lock is faulty

1. The electric lock is to be

blocking defect

replaced

2. The control module or the

2. The control module or the

electronic block is faulty

electronic block is to be

replaced

Electric lock of door defect

«door»

−•••

●○●●○

○●○●○

1. The door is poorly closed

1. The door is to be closed to

feel a lock click

2. Distortion of electric lock of

2. To eliminate the distortion

door blocking during

of electric lock of door

installation

blocking

3. No electric contact between

3. To check with multimeter

the electronic block and the

instrument availability of

electric lock of door blocking

electric circuit between the

(break of strip wire)

electronic block and the

electric lock of door blocking.

In case of break - to replace

strip.

4. The electric lock of door

4. To replace the electric lock

blocking is faulty

5. The control module or the

5. To replace the control

electronic block is faulty

module or the electronic block

Triac of electric motor defect

«F 12»

−••

●●○○○

○●●○○

The control module or the

To replace the control module

electronic block is faulty

or the electronic block

Malfunction of variable data file

«F 13»

−•••

—

○●●○●

The control module or the

To replace the control module

electronic block is faulty

or the electronic block

Software

malfunction

«F 14»

−•••

—

—

1. The chain between control

1. To replace the chain

(requests on I2C are not

module and interface module

processed)

is faulty.

2. Interface module is faulty.

2. To replace interface

module.

3. Control module is faulty.

2. To replace control module.

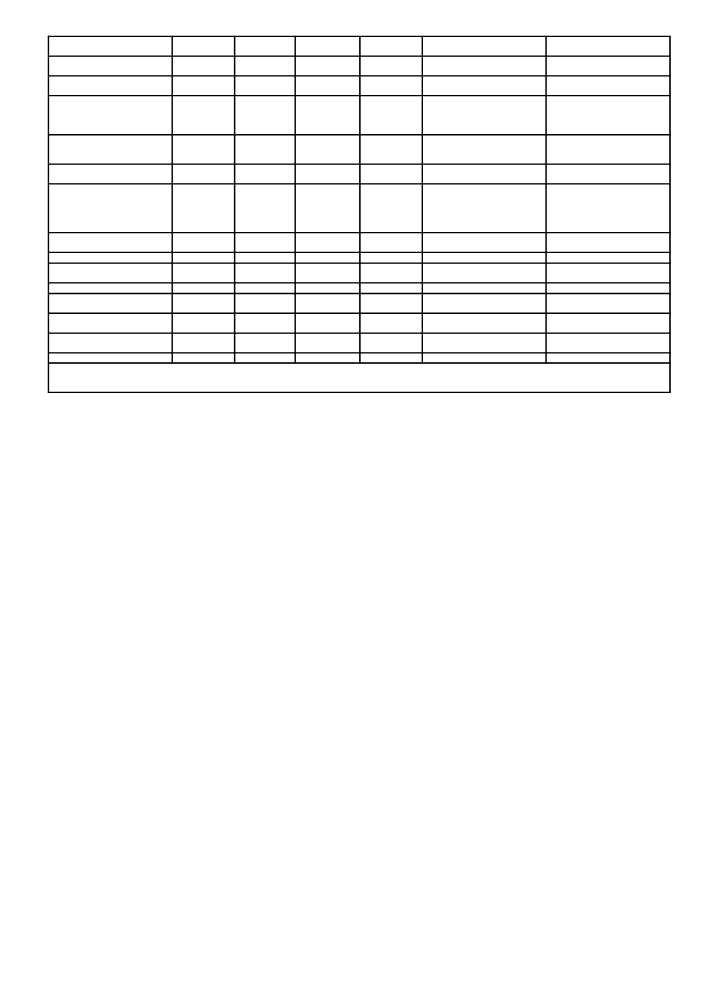

Water leakage from tank

«F 15»

-

○○○●○

—

1. Defective connection or

1. To check availability of

break in rubber articles

clamps and quality of rubber

articles connections. If

necessary, to replace them.

2. Divergence of tank covers

2. To check gripping of tank

covers screw

3. Aqua-stop switch is faulty

3. To replace aqua-stop

4. Water leakage through door

4. To restore hermiticity or to

gasket or seal

replace door gasket or seal

5. The crack in tank cover

5. To replace tank cover

6. Water leakage through

6. To replace dispenser

dispenser

7. The control module or the

7. To replace the control

electronic block is faulty

module or the electronic block

Heating is on constantly

—

-

○○○○●

●○○○○

Electronic block (heater relay)

.To replace the electronic

is faulty

block

Level sensor malfunction

—

-

●●●●○

—

Level sensor is faulty

To replace level sensor

1)

Black circle means that indicator on interface module burns

2)

In WMs with

8 interface electronic block shall be replaced

3)

Only for WMs with aqua-stop