Mechanical refurbishment of Simson S51b

The carburetor retrofit kit included a new copper shaft for the float.

Yeah

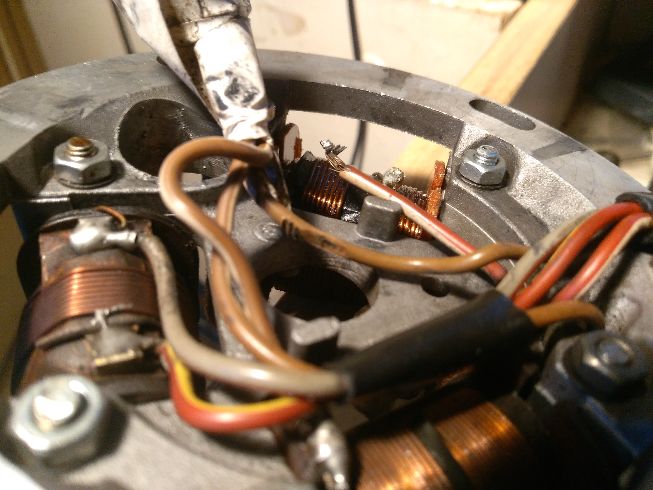

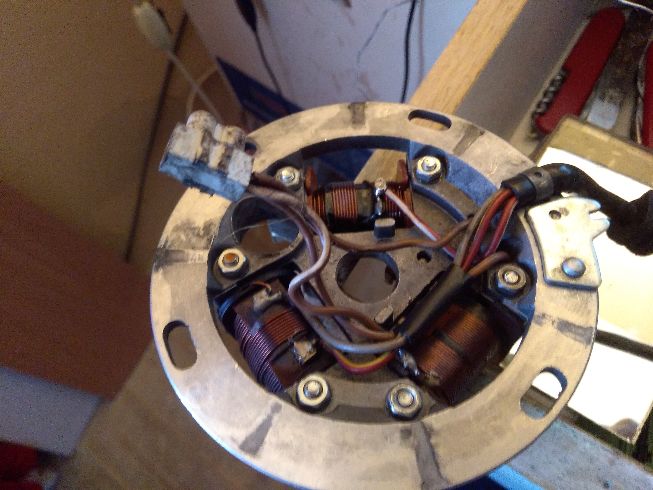

... One solder came off with a minimal force. This could also cause a

charging problem ...

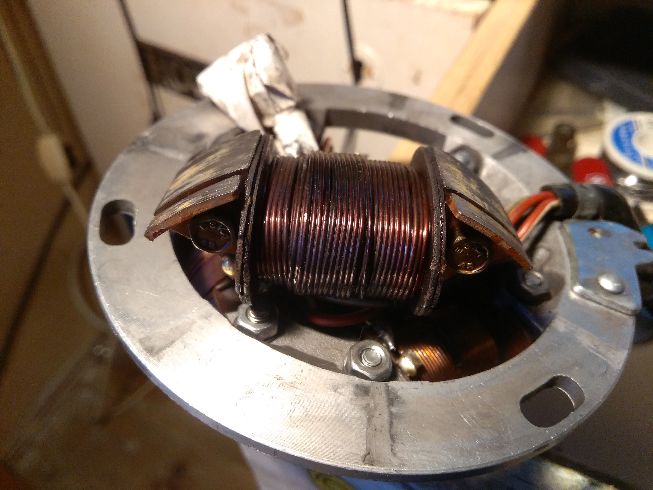

The

lighting coil was burnt to charcoal because a 55W bulb was placed in

the headlamp instead of 35W ...

The

terminal block hidden by the sealing tape is just icing on the cake

:).

That

would be the exhaust ... Did I say there was a little bit of oil

everywhere? Here too.

That

would be the inside. I understand that it is silencer, but it should

not be so silent.

It

didn't work out in a week ...

The

rear lampshades were matte and even the bottom was melted because it

was a 21W bulb instead of a 5W ...

More

and more laughs. Should be slowly assembled ...

Old

and new pipe shaft + spike.

The

old stepping-stone had been refined by something of great skill.

Maybe the drum should have been broken. Is not it?

The

one on the left is new, though it looks worn, but it isn't. I think

he was standing in a warehouse where he was served back and forth.

I

used to smoke a lot because it's a waste product. Later I took it

back and bought it from somewhere else.

Not

very alike...

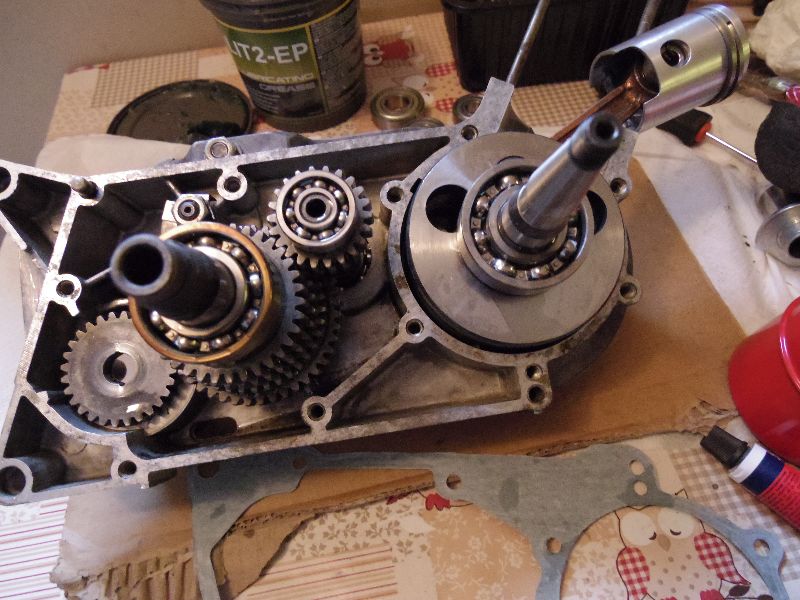

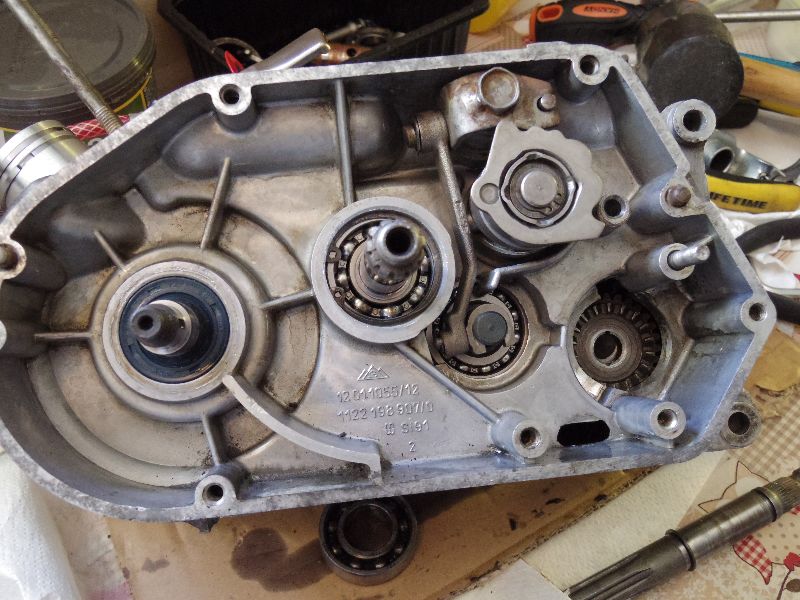

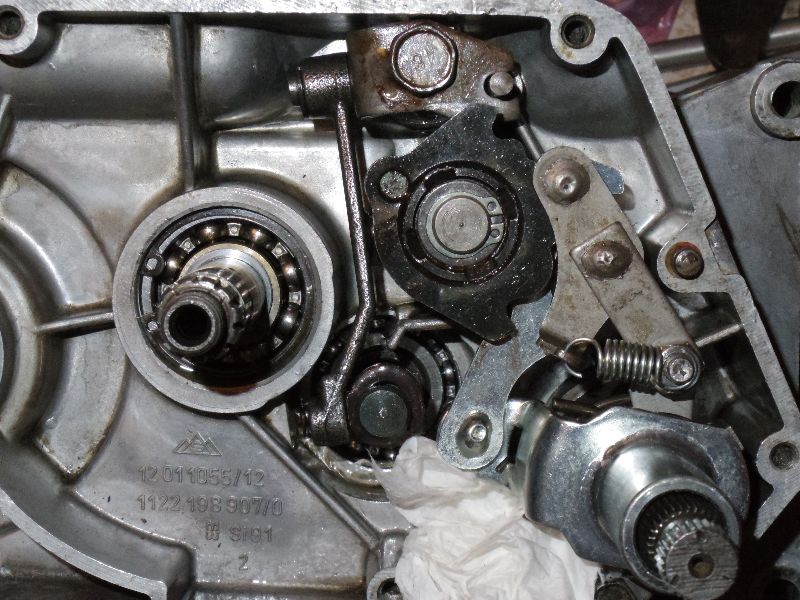

Comes

to gear assembly. The balls have to be greased into the tube shaft,

but they are guaranteed to drop 2-3 times for good.

This is a skill and patience game ...

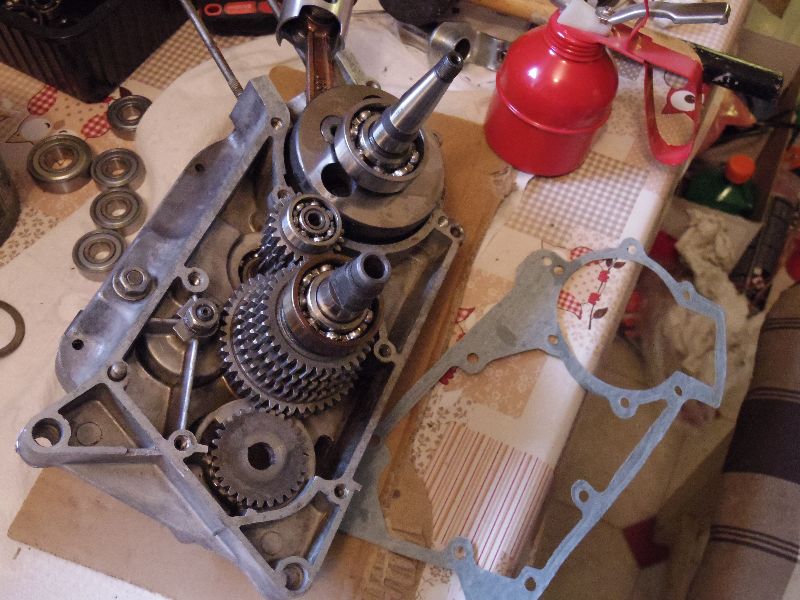

New

bearings ready for use.

I

washed them all with a brake cleaner to be grease free because they

will swim in oil anyway, but before that they get some heat ...

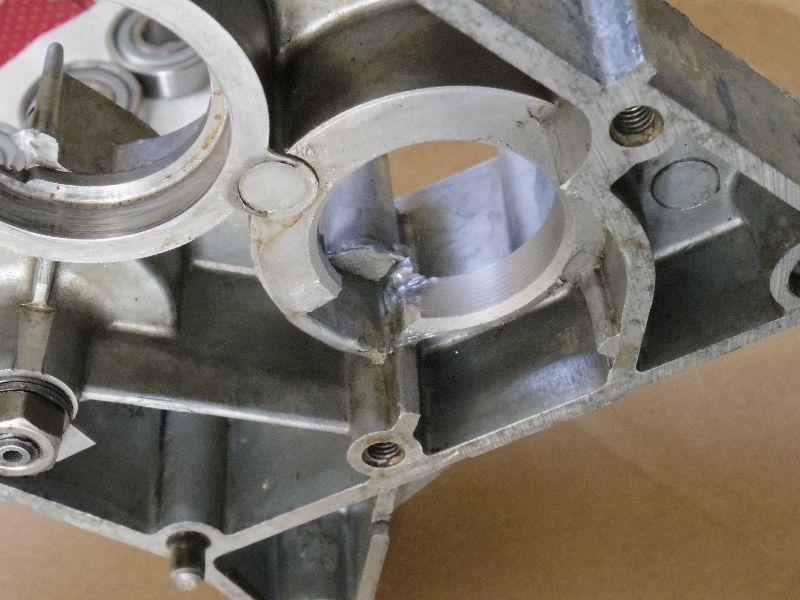

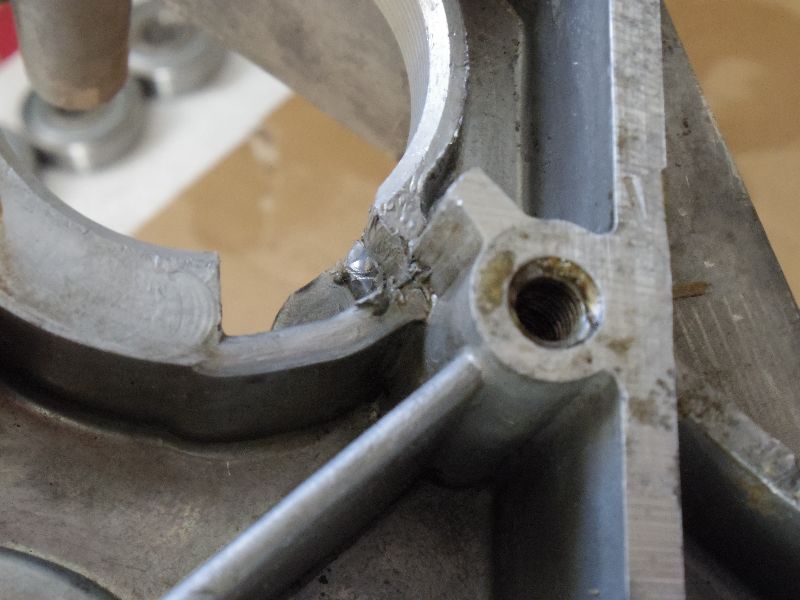

Unfortunately,

the kick arm had an injury to the cast.

It

had to be sanded to prevent it from getting stuck.

I

lit it a little while looking at the temperature with a laser

thermometer. 80-90C is enough for it

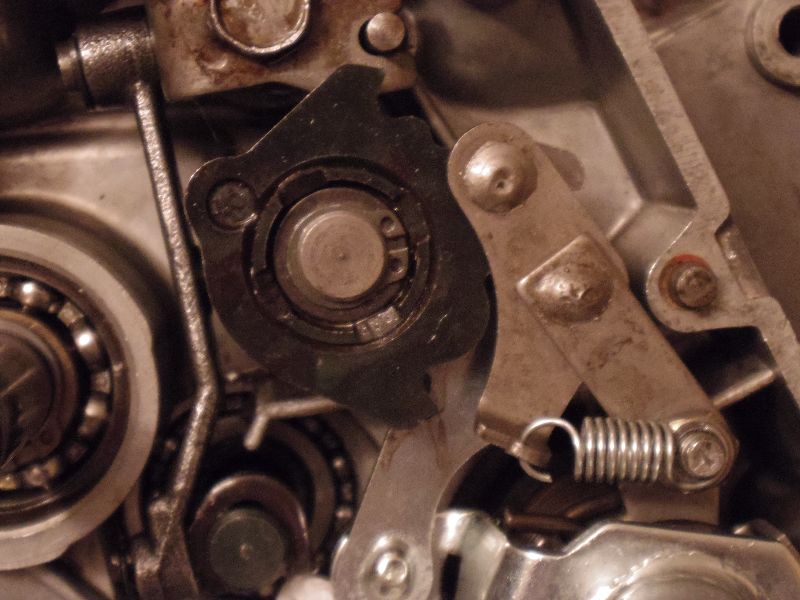

Here,

too, the peasant saved the zigzag ring ...

The

drum gear butt is cracked ... I replaced that too.

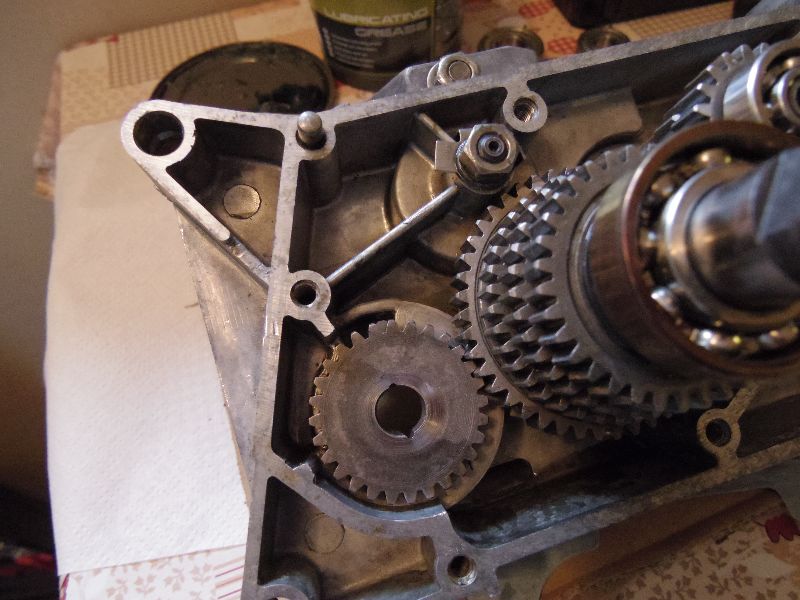

Don't

forget this gear. Many people run down ...

One

of the bearings was slightly overheated, so it became discolored ...

However, it almost fell on the shaft due to thermal expansion.

There

might be a paper seal that I applied on both sides with heat and oil

resistant silicone adhesive.

The other half of the block was heated for approx. It slid to 100C and rolled into place without any effort.

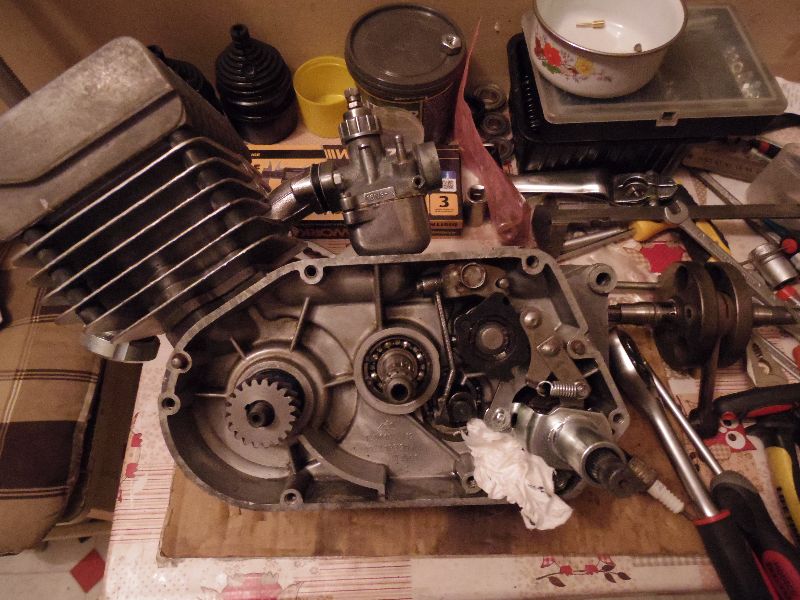

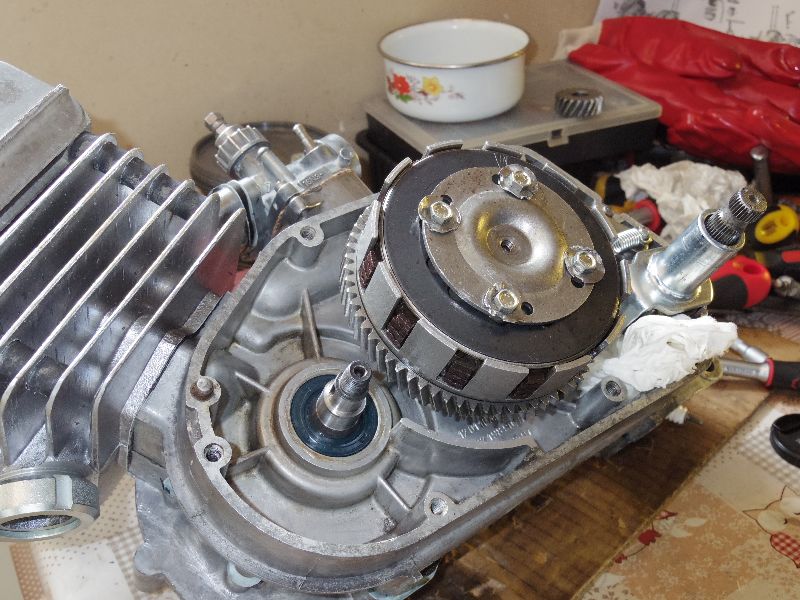

Comes

with the gearbox and clutch assembly.

Did

I tell you that some bumblebee peasant could have fun in front of

him? The drum clamp has been cleared ...

The

picture shows the new and the old ... Well this could have caused an

inaccurate change. I just don't understand why I had to?

There's

also a piece of sidekick broken ... You haven't been able to break it

lately, because the oxide layer is munching on it.

I

polished it a bit because it was full of bumps and scratches.

The

carburetor is in place.

This

ring is the most hateful in the world. She likes to fall off ... It's

worth connecting the two ends with a piece of wire...

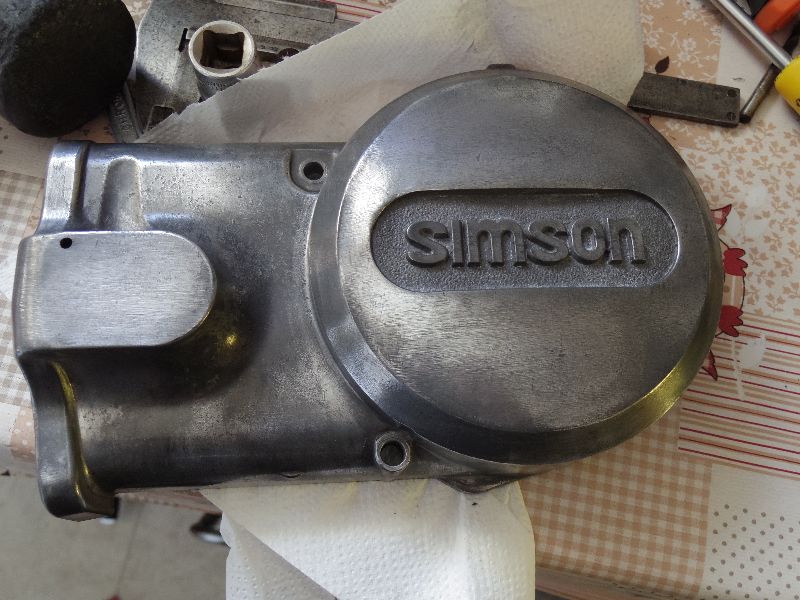

Nice

new parts lined up inside ...

It

develops...

The

clutch is on it as well. Here, too, the blades and plate springs had

to be replaced because it was totally damaging and stuck.

The

crankshaft gear was hard to put on. Finally, I changed my mother

because she was quite injured in the thread ...

It

was the boot...

I

bought one instead.

The

difference is spectacular.

The

km clock is quite simply dusty and broken.

It

is a little struck and worn. It had a broken bulb anyway. It's good

that you always chewed the spiral ...

dismantled

Made

of new index copper plate. It won't rot.

A

little chronological error ...

The

km clock spiral drive was worn out and had to be replaced as well.

There

was so much oil in it. approx. one and a half times the standard ...

It's good to be refilled if it leaks ...

I do not wonder that everything was floating in the oil.

It

was reassembled in place of the engine. The frame received some paint

against rust.