DISTILLATION - PROCESSES

UNDER CONSTRUCTION

[Continuous distillation][Pressure swing distillation]

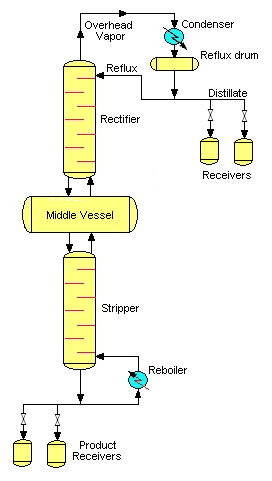

[Batch rectifying] [Batch stripping] [Middle vessel column]

[Batch homoazeotropic distillation] [Batch heteroazeotropic distillation]

Continuous distillation / Rectification

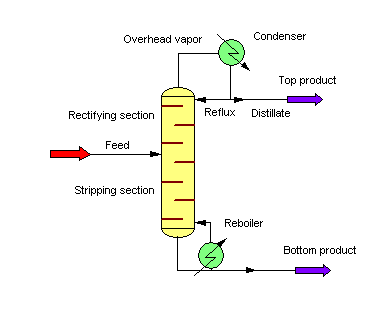

The feed material, which is to be separated into fractions, is introduced continuously at one (or more) points along the column shell.

At the bottom of the column liquid leaves the column, which is partially vaporized in a heated reboiler to provide boil-up, which is sent back up the column. The remainder of the bottom liquid is withdrawn as bottom product.

At the top of the column vapor leaves the column, which is cooled and condensed to liquid in the (overhead) condenser. Part of this liquid is returned to the column as reflux to provide liquid overflow. The remainder of the overhead stream is withdrawn as distillate or top product. In some cases only part of the vapor is condensed so that a vapor distillate can be withdrawn.

The column contains two different sections: stages above the feed stage named rectifying section, and stages from the feed plate to the lowest plate of the column labeled stripping section.

In the column the lighter (lower-boiling) components tend to concentrate in the vapor phase, while the heavier (higher-boiling) components tend toward the liquid phase. The result is the top product becomes richer in light components as the feed and the bottom product becomes richer in heavy components as the feed.

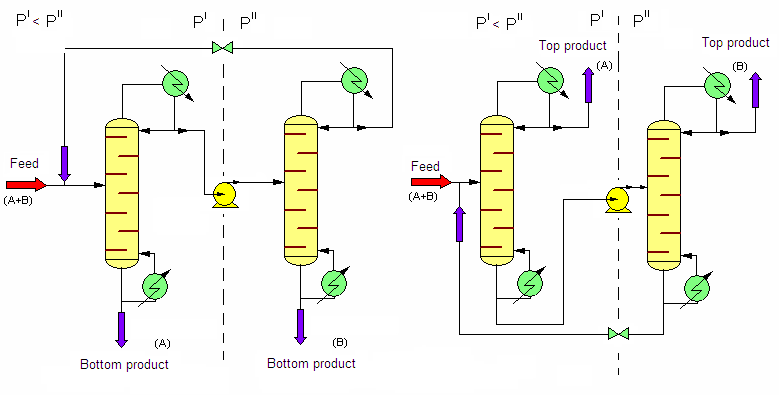

The two columns are working at different pressures. The A-B binary mixture forming minimum azeotrope is fed into the first column (Fig. a) working at lower pressure. Pure A is removed as bottom product and a mixture of nearly azeotropic composition at this pressure is the distillate. This stream is fed into the second column. Since the pressure has changed the composition of the feed is not the azeotropic one at this higher pressure. Hence pure B can be produced as bottoms and a nearly azeotropic mixture as distillate, which is recycled to the first column.

A similar system (Fig. b) is used for maximum azeotropes. In this case the pure components are obtained as distillate and the bottoms of the second column is recycled.

a) Separation of minimum boiling point azeotropic mixtures .......................b) Separation of maximum boiling point azeotropic mixtures

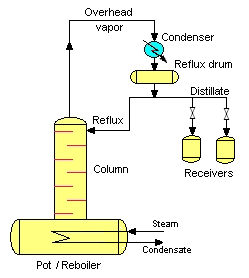

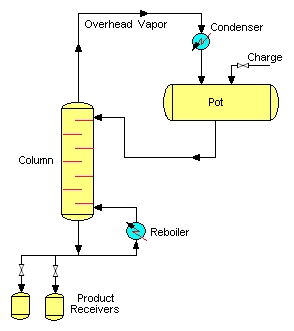

Batch distillation is a very frequent separation process in the pharmaceutical, fine-chemical and specialty industries. It is preferable to continuous distillation when the composition and quantity of the mixture to be separated (charge) vary widely from period to period.

Batch homoazeotropic distillation and Batch heteroazeotropic distillation

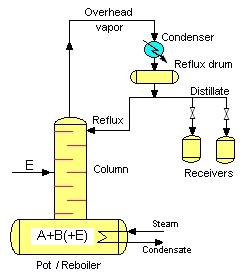

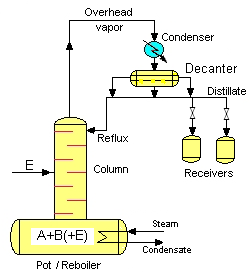

For the separation of such mixtures where the two components (A and B) form an azeotrope or the relative volatility is near to the unity, a special distillation method must be applied such as the homoazeotropic (extractive) or the heteroazeotropic (heteroextractiv) distillation. In both cases a third component (entrainer E) is added to the mixture that makes the separation of A and B possible without the formation of new azeotropes (homoazeotropic distillation) or by the formation of at least one heteroazeotrope (heteroazeotropic distillation).

Three different cases are possible for the addition of the entrainer:

1, Batch Addition of the Entrainer: The total quantity of the entrainer is added to the charge before the start of the procedure.

2, Continuous Entrainer Feeding: The total quantity of the entrainer is introduced continuously to the column.

3, Mixed Addition of the Entrainer: The combination of the batch addition and continuous feeding of the entrainer. We added one part of the entrainer to the charge before the start of the distillation and the other part continuously during distillation.

............................

............................

Home Definitions Processes Pictures Articles Books Links Conferences Contact - Design by GM 2006 -