Mowi forecasts 4 percent jump in 2025 production, lower salmon farming costs

If 50 units are halfway through the assembly process, the WIP Inventory would include the cost of steel ($50 x 50 units) and half the labor costs ($10 x 50 units), totaling $3,000. This example highlights how WIP Inventory reflects ongoing production costs and underscores the importance of accurate tracking and valuation. The cost of production is a complex and dynamic element that requires why you shouldn’t claim your child as a dependent careful consideration and strategic management. By examining it from various angles and implementing best practices, manufacturers can optimize their operations, reduce costs, and ultimately enhance their market position. The interplay of these factors underscores the importance of a holistic approach to understanding and managing production costs in the manufacturing sector.

Which activity is most important to you during retirement?

It is important to record and store the cost data in a systematic and secure manner, to ensure the integrity and availability of the cost data for the preparation and presentation of the cost report. It is also important to backup and archive the cost data regularly, to prevent data loss or damage. Once the relevant cost categories and subcategories are identified, the next step is to collect the cost data from reliable and verifiable sources. Reliable sources are those that provide accurate and complete information that can be trusted and relied upon.

What are the main reasons of using a job-order costing system?

Conversely, too little WIP might suggest a lack of demand or problems with upstream suppliers. IntraFish supplies the breaking news and insight to inform better business decisions throughout the value chain, from the sea to the supermarket shelf. We follow strict ethical journalism practices, which includes presenting unbiased information and citing reliable, attributed resources. The data should be visualized and presented in a way that is easy to understand and communicate.

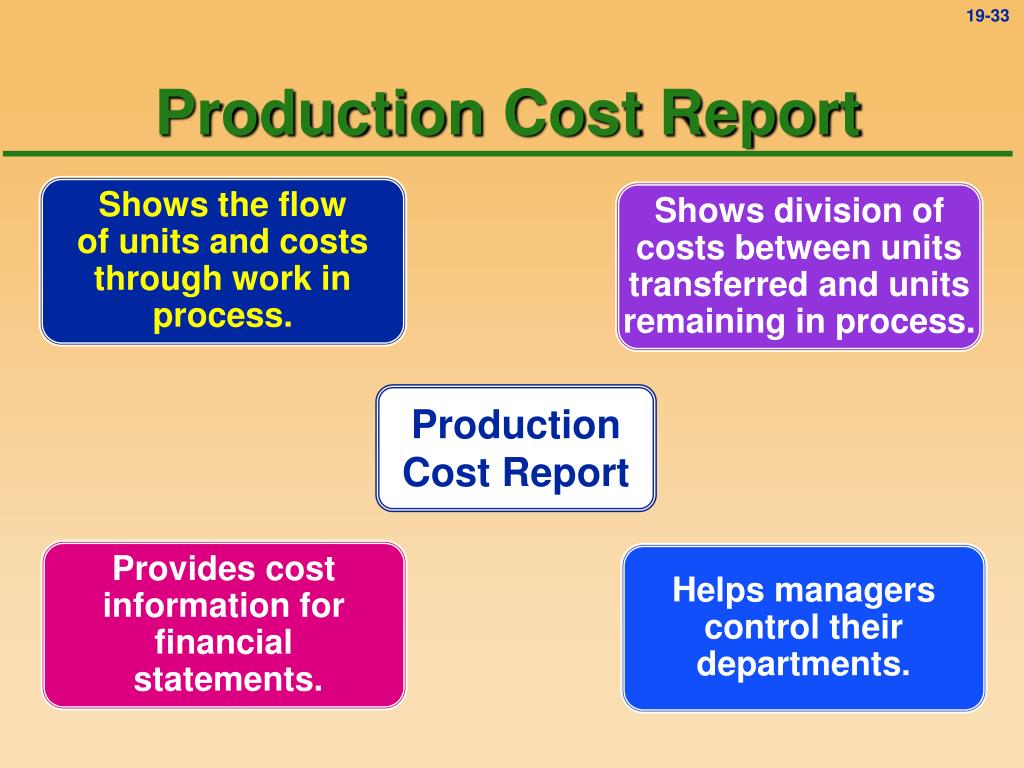

Cost of Production Report: Unraveling the Cost of Production Report in Manufacturing

The data should be verified for any errors, inconsistencies, or discrepancies. The data should also be categorized and classified according to the cost elements, such as direct costs, indirect costs, fixed costs, variable costs, and overhead costs. Depending on the scope and purpose of the cost report, different cost categories and subcategories may be relevant.

However, if thecompany produces more or fewer units than were produced in May, theunit cost will change. This is because the $62 unit cost includesboth variable and fixed costs (see Chapter 5 for a detaileddiscussion of fixed and variable costs). By considering these points, a comprehensive understanding of direct materials and labor costs can be achieved.

Review problem 8.5

Communicating and presenting the cost report effectively will help to convey the key messages, insights, and recommendations of the report, as well as to engage and influence the stakeholders. For example, an effective communication and presentation may involve the use of a summary, a visual aid, and a call to action. This means delivering the cost report to the intended audience, using the appropriate medium and channel, such as email, print, online, etc. The cost report should be distributed and communicated in a timely and secure manner, as well as in accordance with the confidentiality and sensitivity of the information. The cost report should also be followed by a discussion, a presentation, or a meeting, to explain and clarify the cost information, as well as to address any questions, comments, or concerns. For example, a cost report for a large and complex project may require more distribution and communication than a cost report for a small and simple project.

- Depending on the scope and purpose of the cost report, different cost categories and subcategories may be relevant.

- A retail chain that used cost reporting to analyze and improve the performance and profitability of different stores and departments.

- The cost of production report is a financial statement that summarizes the total cost of manufacturing a product or service during a specific period.

- Different stakeholders may have different perspectives and expectations on what the metrics mean and how they should be used.

- An example of how to use Excel to prepare a production cost report follows.

The visualization should use appropriate charts, graphs, tables, and diagrams to illustrate the data and highlight the trends, patterns, and outliers. The presentation should use a logical and coherent flow to tell a story and convey a message. The presentation should also use a professional and engaging tone and language to capture the attention and interest of the audience. Starting a nonprofit can be a fulfilling way to make a difference in the community, but it requires careful planning and consideration. A financial professional will offer guidance based on the information provided and offer a no-obligation call to better understand your situation. This team of experts helps Finance Strategists maintain the highest level of accuracy and professionalism possible.

Moreover, understanding the cost of production is essential for pricing strategies, ensuring that products are competitively priced while still generating a profit. Understanding the cost of goods manufactured (COGM) is a critical aspect of managing a manufacturing business. It represents the total cost incurred to produce products that are ready for sale during a specific period.

Verifiable sources are those that provide evidence and documentation that can be checked and confirmed. Some examples of reliable and verifiable sources are accounting records, invoices, receipts, timesheets, contracts, and budgets. It is important to collect the cost data from these sources as soon as possible after the costs are incurred, to avoid errors, omissions, or discrepancies. It is also important to keep track of the source of each cost data item, to facilitate the verification and validation process later. For example, consider a car manufacturer that starts with 100 units of raw steel (valued at $50 each) and incurs labor costs of $20 per unit.

Analyzing cost data provides businesses with valuable insights for decision-making, cost optimization, and profitability improvement. The cost of production report can be used by management to make decisions about how to allocate resources and to improve efficiency. For example, management could use the report to identify areas where costs are high and to take steps to reduce costs. By following these steps, you can create a cost report structure that meets your project and organization needs.